| Sign In | Join Free | My xpshou.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xpshou.com |

|

Brand Name : SUPERISYS

Model Number : RF-HZMTC1208M-112/2k

Certification : ISO\FCC\ROSH

Place of Origin : CHINA

MOQ : one

Price : The price is negotiable in large quantities

Payment Terms : T/T, Western Union

Supply Ability : 1000 per day

Delivery Time : 5-8 Work Days

Stock : In Stock

Description : size11.8*7.8*4.5mm,Precision carrier,RFID carrier bodyHigh-Frequency RFID Tags for Automated Assembly Lines,

working frequency : 13.56MHz

Air port agreement : ISO 15693

Read distance : 0~12mm(Reader-related)

User memory : 112 bytes/2000 bytes

Memory type : EEPROM/FRAM

Rewrite cycle : 100,000 times/10 billion times

Data storage time : 10 years

size : 11.8*7.8*4.5mm

Housing material : PBT

Fixed mode : Glue

IP rating : IP68

Operating temperature : -40°C~70℃

Storage temperature : -40°C~125℃

Metal resistance : Flush mounting with embedded metal

RF-HZMTC1208M,Flush Mounting With Embedded Metal,Precise Code Carrier,

By adding or embedding RFID carriers into work-in-progress items, tooling fixtures, clamps, auxiliary parts, etc., and deploying RFID reading and writing equipment at automated node workstations, interaction with the work-in-progress items can be achieved. This enables a production method of multiple varieties on a large scale, achieving real-time automatic identification of individual products. It automatically connects automated equipment and robots, realizes personalized transmission of processes, defines parameters automatically, and supports scenarios of automated equipment inspection.

When used for automated assembly lines and tool management in machining, the carrier can be directly embedded into tools/fixtures and undergo dynamic balancing tests. The carrier stores information about the tools/fixtures, such as parameters of the tools and work-in-progress items, service life, etc. At the identification nodes, the reader can collect information about the tools/fixtures and work-in-progress items from the carrier, which is then processed by the backend system. This realizes full lifecycle management and automatic loading of machining processes.

For the 3C industry's automated assembly lines, RFID readers are installed at each workstation, and RFID tags are mounted on the jigs/fixtures. The RFID tags are bound to the serial numbers of the production modules. Through RFID automatic identification, functions such as automatic work reporting, product quality tracing, and automatic off-lining of defective products are realized.

| product model | RF-HZMTY60M-112 | RF-HZMTY60M--2K | RF-HZMTY80M-112 | RF-HZMTY80M--2K | RF-HZMTY100M-112 | RF-HZMTY100M--2K | RF-HZMTC1208M-112 | RF-HZMTC1208M--2K |

| Product size |  |  |  |  | ||||

| working frequency | 13.56MHz | 13.56MHz | 13.56MHz | 13.56MHz | ||||

| Air port agreement | ISO 15693 | ISO 15693 | ISO 15693 | ISO 15693 | ||||

| Read distance | 0~8mm(Reader-related) | 0~12mm(Reader-related) | 0~12mm(Reader-related) | 0~12mm(Reader-related) | ||||

| User memory | 112 bytes | 2000 bytes | 112 bytes | 2000 bytes | 112 bytes | 2000 bytes | 112 bytes | 2000 bytes |

| Memory type | EEPROM | FRAM | EEPROM | FRAM | EEPROM | FRAM | EEPROM | FRAM |

| Rewrite cycle | 100,000 times | 10 billion times | 100,000 times | 10 billion times | 100,000 times | 10 billion times | 100,000 times | 10 billion times |

| Data storage time | 10 years | 10 years | 10 years | 10 years | ||||

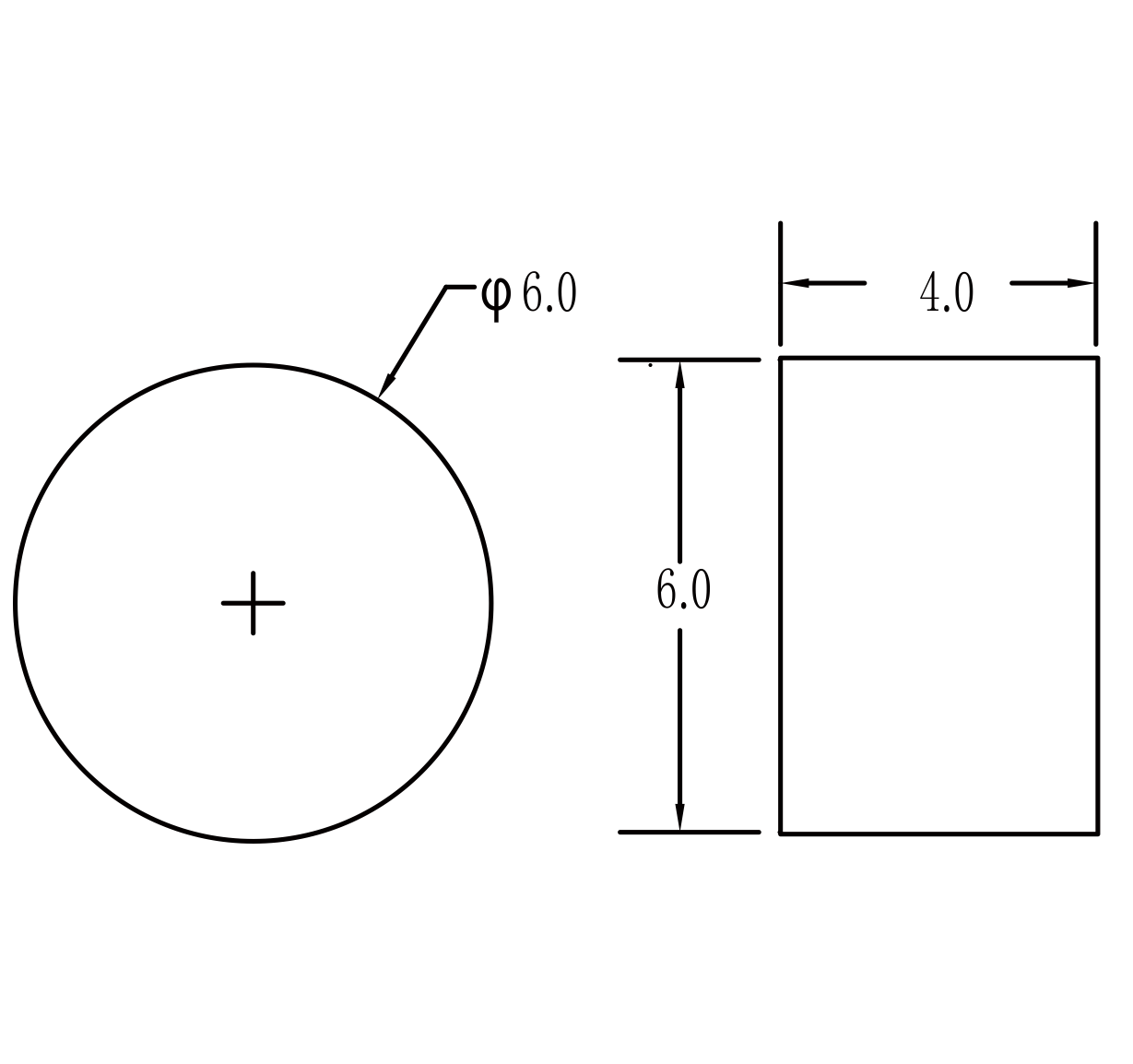

| size | Φ6*4mm | Φ8*4.5mm | Φ10*4.5mm | 11.8*7.8*4.5mm | ||||

| Housing material | PBT | PBT | PBT | PBT | ||||

| Fixed mode | Glue | Glue | Glue | Glue | ||||

| IP rating | IP68 | IP68 | IP68 | IP68 | ||||

| Operating temperature | -40°C~70℃ | -40°C~70℃ | -40°C~70℃ | -40°C~70℃ | ||||

| Storage temperature | -40°C~125℃ | -40°C~125℃ | -40°C~125℃ | -40°C~125℃ | ||||

| Metal resistance | Metal surface or insert mounting | Metal surface or insert mounting | Metal surface or insert mounting | Metal surface or insert mounting | ||||

|

|

RF-HZMTC1208M:12*8*4.5mm Anti-Metal High Frequency RFID Data Carrier Images |